Considering the fact that press brake machines might be fitted with a wide range of punches and dies, they may be used for nearly any sheet or plate metal shaping programs. The most common are:

Sheet metal bending solutions are very similar in that their stop purpose is to transform metal buildings into the desired varieties. Even so, they differ in Procedure.

These precision-engineered seals are made to avoid oil leakage from hydraulic cylinders together with other pressurized compartments, making certain constant performance and longevity of your equipment.

Have you ever wondered how a flat sheet of metal is reworked into a posh form? Press brakes are classified as the unsung heroes on the production entire world, bending and shaping metal…

Should you position the bends as well near to one another in design and style, it could potentially cause alignment concerns and improve the residual stress. As a result, an correct distance among them is crucial, no less than thrice of thickness.

Magnetic goniometers are versatile angle-measuring gadgets that can be securely attached to press brake tables or immediately onto bending tools. These precision instruments are equipped with impressive magnets, allowing for for speedy and secure positioning without having further fixtures.

A managed axis, or machine axis, refers to a certain motion on the machine that is certainly measured by an encoder and controlled by the computer by means of a motor or actuator.

In order to deliver higher-excellent machined parts which has a sleek appearance, it’s essential to consider some vital components associated with CNC machining.

1mm. The bending system occurs because the punch descends, making use of managed pressure to deform the fabric against the die’s profile.

Thus, it may be mentioned that the verb “brake” in the context of a press website brake refers to the machine that bends sheet metal.

Watch PDF catalogues together with other on the net documentation

These built-in systems can substantially enhance productiveness and lessen the want for handbook measurements.

Press brake clamps are necessary factors in the tooling system, comprising regular clamps and swift-adjust clamping products suitable for immediate top punch exchanges. These clamping systems play a crucial function in optimizing the setup procedure and enhancing General productivity.

These Handle units are generally mounted at a single finish of your press brake and function the main interface for programming and functioning your entire system.

Bradley Pierce Then & Now!

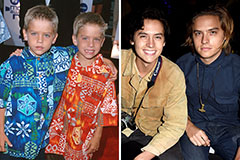

Bradley Pierce Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Molly Ringwald Then & Now!

Molly Ringwald Then & Now! Tatyana Ali Then & Now!

Tatyana Ali Then & Now! Marla Sokoloff Then & Now!

Marla Sokoloff Then & Now!